How to choose the right bearing?

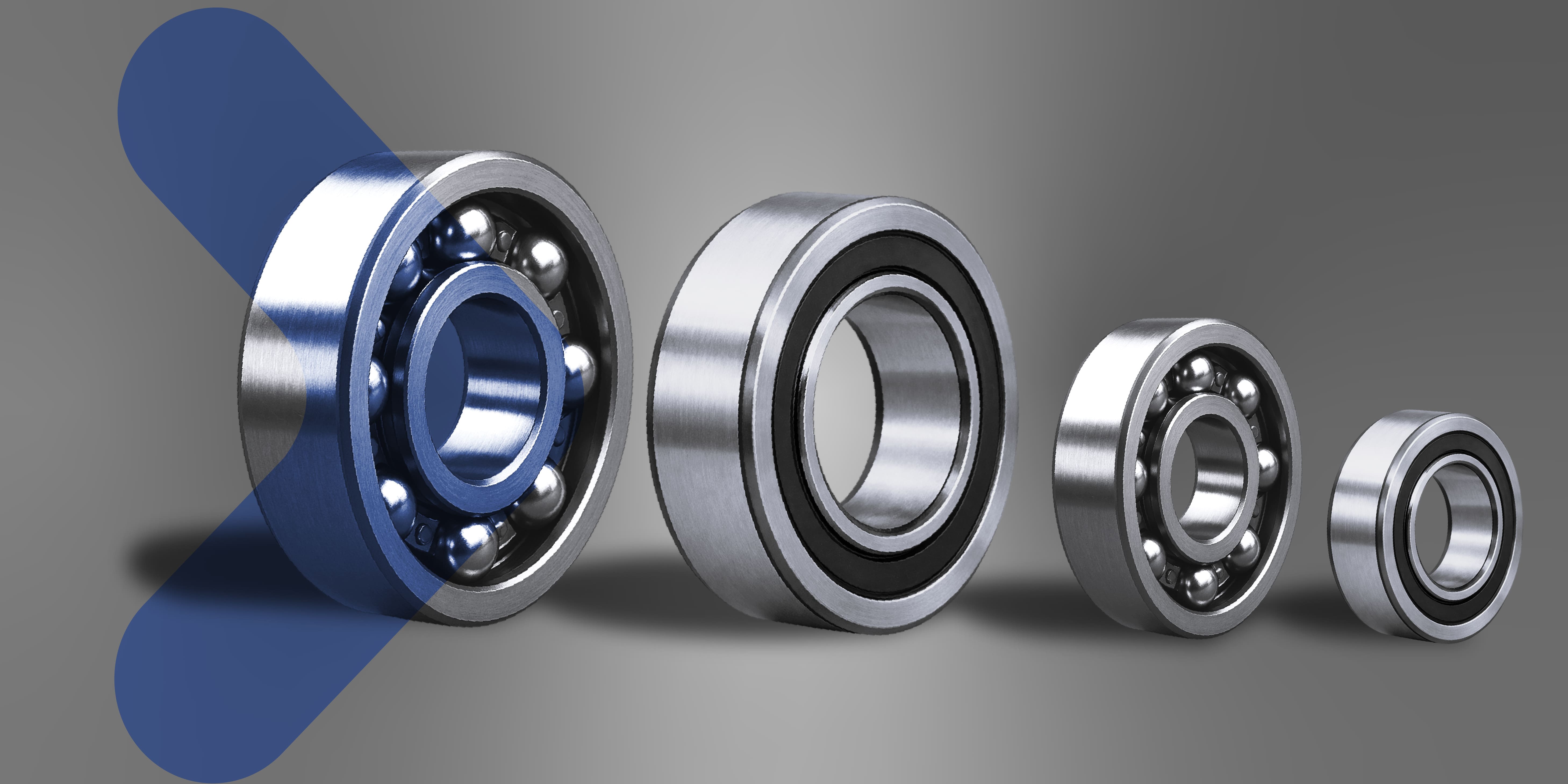

Bearings are an essential component in the proper functioning of many mechanical devices. From heavy industry to household appliances, their selection determines the durability and performance of systems.

👉 According to SKF, choosing the wrong bearing can cause up to 50% of mechanical failures.

See our bearings

Why is the choice of bearing so important?

An incorrectly sized or unsuitable bearing can result in:

- premature wear

- costly production stoppages

- overheating

- even serious mechanical failures

Choosing the right bearing means investing in the durability and safety of your installations.

👉 At Texime, we support professionals in securing every industrial application.

Types of bearings

Most common types of bearings |

Description |

|---|---|

| Ball bearings | Suitable for high speeds and moderate loads, the most common type. |

| Cylindrical roller bearings | For heavy radial loads and high stresses. |

| Tapered roller bearings | Support combined loads (radial + axial). |

| Needle bearings | Compact, perfect for saving space. |

| Spherical bearings | Suitable for misalignment. |

| Sealed bearings / stainless steel | Ideal for harsh environments (dust, humidity). |

Types of bearing loads

→ Radial load:

Force perpendicular to the bearing axis.

→ Axial load:

Force parallel to the axis.

→ Combined load:

A combination of both.

Speed, misalignment, temperature: key factors in bearing selection

After load, other criteria can completely change your bearing selection. These factors are crucial to ensuring the performance and durability of your installation.

→ Rotational Speed

Some bearings can withstand very high speeds (up to 40,000 rpm for precision ball bearings), while others can withstand much lower speeds.

Ball bearings: suitable for high speeds.

Roller bearings: designed for heavy loads, but at more moderate speeds.

→ Misalignment

Si vos arbres ou montages ne sont pas parfaitement alignés (flexion, déformation, vibration), il faut privilégier un roulement auto-aligneur.

Solution : roulements à rotule sur billes, spécialement conçus pour absorber les écarts d'alignement.

→ Temperature

A standard bearing operates between –20°C and +120°C. Beyond this range, the materials and lubricants must be adapted.

Examples of specific environments: foundries, cryogenics, food processing.

→ The more complex the constraints, the more expertise is required to make the right choice. This is where Texime's support makes all the difference.

Technical criteria to be taken into account

► Speed : affects the durability and type of bearing.

► Temperature : Thermal conditions affect materials and lubricants.

► Environment : Dust, humidity or chemicals require specific protection.

► Tolerances : Internal play and tolerances must comply with ISO 281 standards.

Common mistakes to avoid and their impacts

Incorrect bearing selection can lead to breakdowns, costly production stoppages and even accidents.

Neglecting axial load: causes premature wear.

Underestimating speeds: leads to overheating and rapid deterioration.

Poor lubrication: accelerates bearing wear.

Bearing unsuitable for the environment: may result in loss of warranty and breakdowns.

Final checklist

✔ Load capacity

✔ Rotational speed

✔ Alignment

✔ Environmental conditions

✔ Dimensions

✔ Maintenance

✔ Accuracy

💬 Need advice?

Contact the Texime team: web@texime.com or by phone at 03.27.21.18.51

Discover all the bearings we propose.